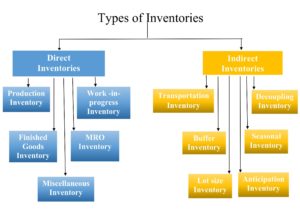

Types of Inventories/Classification of Inventories

Inventories are generally classified into following types:

-

Direct Inventories

These includes such items which are directly used for production or manufacture and are a part of the goods/services produced or provided. Direct Inventories can be further classified into following types:

i. Production Inventory

Items such as raw materials, components and subassemblies used to produce the final product.

ii. Work-in- progress Inventory

The components which are in the process, neither raw material nor finished food but semi finished goods lying in machines or in factory awaiting completion is called work in progress. The control of WIP helps in many ways:

a. To maintain uniform production

b. Flexibility in planning each operation

c. Reduces material handling cost

d. Checks the wastage

iii. Finished goods inventories

This includes the final products ready for dispatch to consumers or distributors. After production. The finished goods may be stocked to meet varying market demands .It helps in the following ways:

a. It is economical to have inventory than constantly placing orders.

b. It is impossible to produce instantaneously on demand.

c. Shortage of store may be unacceptable

d. It helps in efficient scheduling of production

e. Products can be displayed for the consumer.

iv. MRO Inventory

Maintenance, repair and operating items such as spare parts and consumable stores that do not go into the final product but are consumed during the production process.

v. Miscellaneous Inventory

All other items such as scrap, obsolete and unsaleable products, stationary and other items in office, factory and sales department etc.

-

Indirect Inventories

Indirect inventory includes such items which are required for manufacturing production of goods and services are not a part of the finished goods. For example, fuel, oil, coolants, lubricants, maintenance, spare parts, tools etc. in the inventory of every production enterprise but these does not become a part of the goods produced. Indirect inventories are of following types:

i. Transportation Inventory

These are also called transit, pipe line or movement inventories. They consist of items that are currently under transportation e.g. coal being transported from coal fields to a thermal plant.

ii. Buffer inventories

They are required as protection against the uncertainties of supply and demand. A company may well know the average demand of an item that it needs but the actual demand may turn out to be quite different. Similarly, the average delivery time may be known but actual delivery time may be more due to some unforeseen reasons. Such situations require extra stock of the item to reduce the number of stock outs or back orders. This extra stock in excess of the average demand during the lead time is called buffer stock.

iii. Decoupling Inventories

They are required to decouple or disengage the different parts of the production system. For an item that requires processing on a series of different machines with different processing times, it is a must to have decoupling inventories of the item in between the various machines for smooth and continuous production. The decoupling inventories act as shock absorbers in case if varying work rates, machine breakdowns or failures etc.

iv. Seasonal Inventories

Demands in many cases are seasonal and he inventories have to be maintained to meet such high seasonal demands economically. The demand for cooler or ACs before summer season, the demand for geysers before winter and demand of crackers before Diwali are some examples. Since it is known when the demands are going to increase it is possible to stock inventories to meet such seasonal demands.

v. Lot-size Inventories

These are held to take advantages of discounts which are usually available for purchase of large quantities. Lot sizes or cycle inventories are held by making purchases in lots rather than for numbers which are exactly required. Many a time the manufacturers of items like steel, cement, paints, lubricants sell to big users in lot sizes and provide them the advantage of price-cuts.

vi. Anticipation Inventories

These inventories are stocked in anticipation of an event like major promotion programme being launched for display at exhibition or for meeting the customer demand for the plant shut down period for maintenance.